jola@valvulasjola.com

Título de diapositiva

Escriba su subtítulo aquíBotón

Título de diapositiva

Escriba su subtítulo aquíBotón

Título de diapositiva

Escriba su subtítulo aquíBotón

Documentation

DOCUMENTATION

(A) INSTRUCTIONS FOR INSTALLATION

- CONNECTION FLANGES -

Our valves are designed and manufactured to be mounted between flanges DIN PN6, DIN PN10, ANSI 150 #, ANSI 300 #, JIS 5K AND JIS 10K. However, they can also be installed between flanges of other standards, as long as the clearance of the disc and the inner diameter of the flange is guaranteed.

The inner diameter of the flanges must be larger than that part of the disc exceeding the body.

- PREPARATION -

Before installation, clean the valves, the gaskets and the pipe flanges carefully. Check that the flanges are aligned and parallel. If there are any axial forces in the pipeline, such as thermal expansions, they must be compensated for, by using expansions joints whenever necessary.

- SHAFT POSITION AND FLOW DIRECTION -

Our valves are recommended to be installed in horizontal position because the self-cleanning action is ensured and because the weight of the valve disc is distributed over the bearings.

Taking this into consideration, the bottom half of the disc is recommended to be opened against the direction of the flow, when opening the valve.

- MOUNTING -

Our valves must be centred in the flanges through the four centering holes situated in the body necks. Ensure that the disc can be turned through 90 degrees without touching the pipe flanges. Then, tighten the flange bolts in cross sequence, ensuring contact between the valve body, the gaskets and the pipe flanges. Torque all bolts.

The packing gland area must not be insulated.

Upon start up, the packing gland must be checked for tightness and retightness if necessary, to assure

the total tightness through the actuated shaft. Excessive tightness must be avoided, because this will increase the shaft friction and the loss of elasticity of the packing.

(B) INSTRUCTIONS FOR MAINTENANCE

Inspection and retightening of the packing will become necessary from time to time, once the valves have been put into operation. Excessive tightening of the packing gland must be avoided.

Retighten the flange bolts after a long operation time.

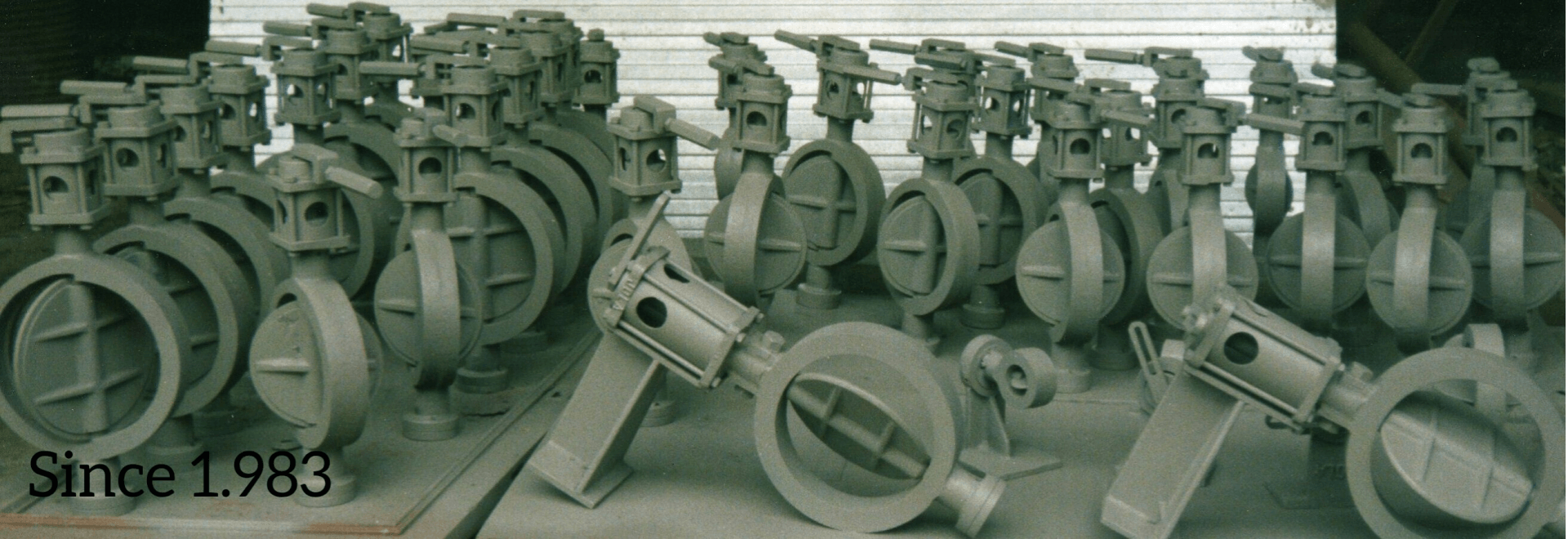

(C) FINISHING

All our valves have a finishing process that consists of:

- Automatic Shotblasting.

- Cleaning of impurities and drying.

- Double layer of grey aluminium anticaloric paint for high temperature.

(D) PAINTING

- DESCRIPTION AND USES -

This is an aluminium paint for finishing, made to be used in surface painting works where heat is found. It is made basically of pure aluminium paste, properly selected, combined with an element whose main component is silicon resin.

- TECHNICAL CHARACTERISTICS -

specific weight: 0.98

colour: aluminium

brightness: metallic high

viscosity: Aprox. 20 seconds (Copa Ford nº 4)

solids in volume: 22 %

efficiency: theoretical: 10 m /litre

practical: 8 m /litre

drying time: to dust: 15 minutes

to the finger: 20/25 minutes

complete: 4 hours

re-paint: 24 hours

dry thickness per coat: 20/25 micra.

- RESISTANCES -

In those cases where there is no corrosion problem, this aluminium paint can be used on metallic surfaces, previously cleaned. It can be used on hot surfaces. If the temperature of the substrat is higher than 60º C. / 80º C., this finishing anticaloric aluminium must be prepared before use.

- CONNECTION FLANGES -

Our valves are designed and manufactured to be mounted between flanges DIN PN6, DIN PN10, ANSI 150 #, ANSI 300 #, JIS 5K AND JIS 10K. However, they can also be installed between flanges of other standards, as long as the clearance of the disc and the inner diameter of the flange is guaranteed.

The inner diameter of the flanges must be larger than that part of the disc exceeding the body.

- PREPARATION -

Before installation, clean the valves, the gaskets and the pipe flanges carefully. Check that the flanges are aligned and parallel. If there are any axial forces in the pipeline, such as thermal expansions, they must be compensated for, by using expansions joints whenever necessary.

- SHAFT POSITION AND FLOW DIRECTION -

Our valves are recommended to be installed in horizontal position because the self-cleanning action is ensured and because the weight of the valve disc is distributed over the bearings.

Taking this into consideration, the bottom half of the disc is recommended to be opened against the direction of the flow, when opening the valve.

- MOUNTING -

Our valves must be centred in the flanges through the four centering holes situated in the body necks. Ensure that the disc can be turned through 90 degrees without touching the pipe flanges. Then, tighten the flange bolts in cross sequence, ensuring contact between the valve body, the gaskets and the pipe flanges. Torque all bolts.

The packing gland area must not be insulated.

Upon start up, the packing gland must be checked for tightness and retightness if necessary, to assure

the total tightness through the actuated shaft. Excessive tightness must be avoided, because this will increase the shaft friction and the loss of elasticity of the packing.

(B) INSTRUCTIONS FOR MAINTENANCE

Inspection and retightening of the packing will become necessary from time to time, once the valves have been put into operation. Excessive tightening of the packing gland must be avoided.

Retighten the flange bolts after a long operation time.

(C) FINISHING

All our valves have a finishing process that consists of:

- Automatic Shotblasting.

- Cleaning of impurities and drying.

- Double layer of grey aluminium anticaloric paint for high temperature.

(D) PAINTING

- DESCRIPTION AND USES -

This is an aluminium paint for finishing, made to be used in surface painting works where heat is found. It is made basically of pure aluminium paste, properly selected, combined with an element whose main component is silicon resin.

- TECHNICAL CHARACTERISTICS -

specific weight: 0.98

colour: aluminium

brightness: metallic high

viscosity: Aprox. 20 seconds (Copa Ford nº 4)

solids in volume: 22 %

efficiency: theoretical: 10 m /litre

practical: 8 m /litre

drying time: to dust: 15 minutes

to the finger: 20/25 minutes

complete: 4 hours

re-paint: 24 hours

dry thickness per coat: 20/25 micra.

- RESISTANCES -

In those cases where there is no corrosion problem, this aluminium paint can be used on metallic surfaces, previously cleaned. It can be used on hot surfaces. If the temperature of the substrat is higher than 60º C. / 80º C., this finishing anticaloric aluminium must be prepared before use.